Manufacturing Capabilities | Hovell Tech

Professional Wireless Charger Manufacturing & OEM Services

Explore Hovell Tech’s full-scale manufacturing—from R&D, PCBA, SMT, testing, to certification. Built for OEM/ODM quality and scalable production.State‑of‑the‑art factory, advanced quality systems, and OEM/ODM support for wireless chargers, PD adapters, power banks, and power strips.

How Your Product Comes to Life — A Step‑by‑Step Look Copy:

Our End‑to‑End Manufacturing Workflow

We manage every stage in-house, ensuring quality control, flexibility, and speed. Our process includes:

01.

R&D & Industrial Design

• Component selection: GaN chips, Qi coils, safety ICs

02.

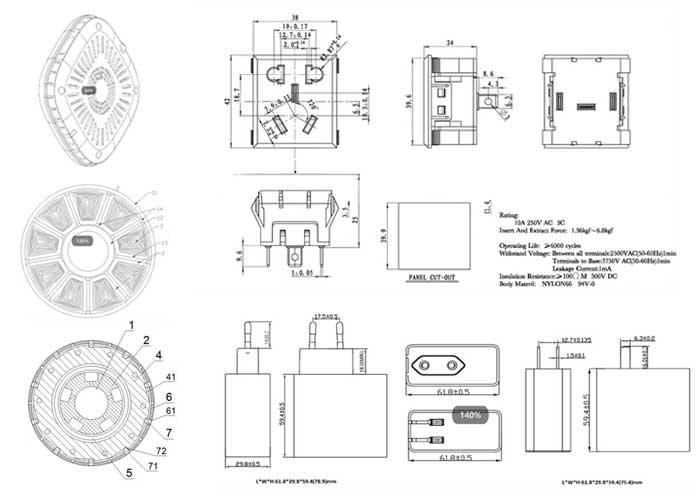

PCB & SMT Production

• PCBA fabrication on high-frequency substrates

• Precision SMT placement & reflow

03.

Housing Assembly & Coil Integration

• Coil soldering, plug blocks, casing, EMI shielding

04.

Quality Control & Testing

• Burn-in, hi-pot, drop & aging tests, AQL inspection

05.

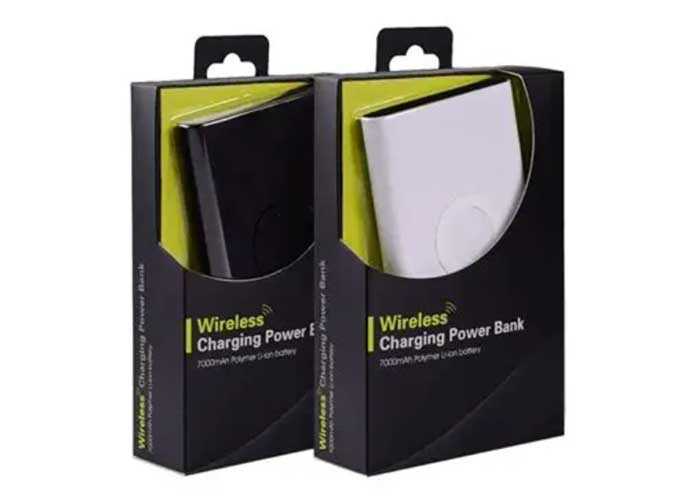

Certification & Packaging

• CE, FCC, UL, RoHS; retail or bulk packaging with customization

06.

Delivery & After‑Sales

• On-time delivery, global logistics support, 1-year warranty

Production View

Factory Capacity & Production Lines

Scale Meets Precision — Built for High Volume & Bespoke Requests

- 10,000 m² facility with SMT, DIP, assembly, aging, and packing lines

- Monthly capacity: 50K wireless pads, 30K PD chargers

- High-frequency PCB, GaN and Qi coil integration lines

Tailored to Your Brand — From Mold to Packaging

Customized OEM & ODM Services

Logo printing

Logo silk-screen, digital print, laser engraving

Private molds & materials

ABS, aluminum, bamboo, eco plastics

Custom packaging

Custom packaging & labels with QR/spec details

Test inspection

Various tests to ensure quality

Some Numbers

Lorem ipsum dolor sit amet, consec tetur adipis.

Satisfied Clients

Projects Completed

Accolades Earned

Lines of Code

Would you like to start a project with us?

Contact us today to get a quick free quote!

Request a Quote

Ready to Work Together? Build a project with us!

OEM/ODM Customization — Made Easy

One-Stop Customization Service

1.Confirm installation scenario (on table / under table)

2.Choose power supply method

3.Select desired functions

4.Finalize custom design & logo

5.Confirm quantity & lead time

6.Sample → Production → Delivery